Share:

More Articles

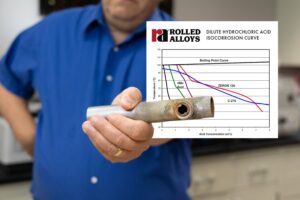

Plasma and laser cutting are fast, productive industrial processes for cutting metal parts. These state-of-the-art machines use high-powered directional beams, capable of scaling up from a computer-generated template while tracing a pattern being simultaneously cut. When the process begins, the area that is being cut will reach a temperature hot enough that it becomes molten.

Watch Hugh explain the difference between Plasma and Laser Processing

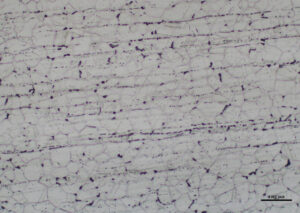

The high-pressure gas supplied by the laser or plasma then forces the material down within the seam, thus severing the material. As a result, there is a resolidified region at the cut surface with a cast microstructure and a heat-affected zone adjacent to the resolidified region. These two processes are not ideal for cutting certain classes of materials including precipitation hardenable stainless steels (17-4, 15-5), martensitic stainless steels (410, 440c), and duplex stainless steels (2205, 2507).