STAINLESS STEEL

Latest Articles

410

410 stainless is a corrosion and heat resistant 12% chromium steel. It is the most widely used of the hardenable stainless steels. Heat treated 410 has mechanical properties comparable to the engineering alloy steel AISI 4130, coupled with the additional benefit of good corrosion resistance. 410 is highly resistant to atmospheric corrosion. Maximum corrosion resistance is obtained by hardening and polishing.

Because 410 is an air hardening steel, it must be given a high preheat, at least 350-400°F before welding, and immediately given a full anneal before the weldment cools. Otherwise the metal will harden, and cracking is likely. Matching composition filler metals are available, AWS E410 covered electrodes and ER410 bare filler wire. Alloy 82 (AWS ERNiCr-3) filler wire has also been used. This nickel alloy is comparatively low strength, and therefore accommodates some of the strain which may otherwise contribute to cracking in the 410 weldment.

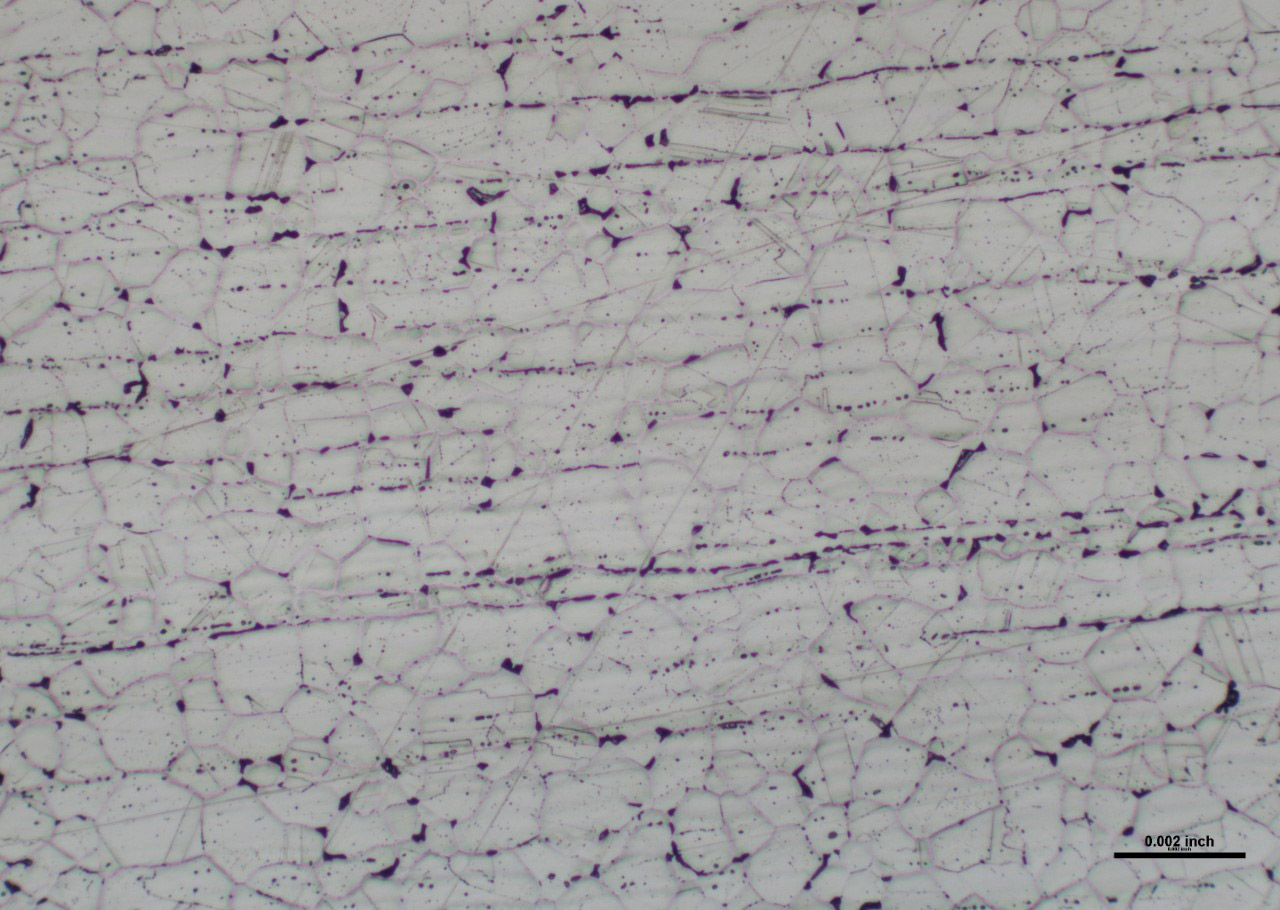

Heat uniformly to 1200-1400°F, remove from furnace and air cool. This should result in Brinell hardness about 187. For maximum softness, heat to 1500-1650°F, furnace cool slowly to 1100°F, after which air cooling is permissible. Brinell hardness should be approximately 155. Heat to 1750-1850°F, soak at heat, and quench in oil. Light sections will also harden by air cooling. 410 will harden to some degree when heated 1500°F and over unless slowly cooled to below the critical temperature. Soak at heat at least one hour, longer for large sections, and air cool. Tempering 410 in the range 750-1050°F results in decreased impact toughness and somewhat reduced corrosion resistance.

- Hardenable stainless which may be tempered as high as 1350°F to produce high impact toughness.

- Oxidation resistant through 1500°F intermittently, 1200°F continuously.

- Corrosion resistant.

Plate, Round Bar, Sheet

UNS: S41000

W. NR.: 1.4006

ASTM: A 240

ASME: SA 240

AMS: 5504

- Press plates

- Petrochemical equipment

- Firearms production

- Gate valves

- Mining machinery

- Distillation trays

Share This Page